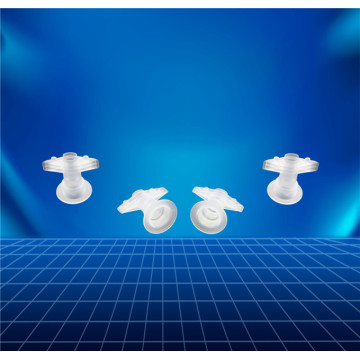

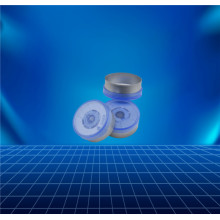

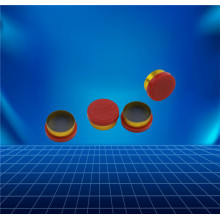

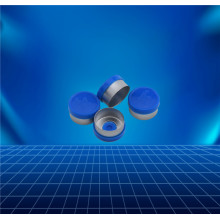

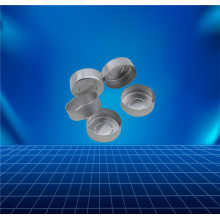

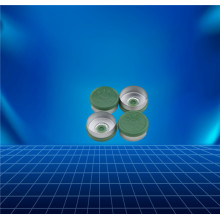

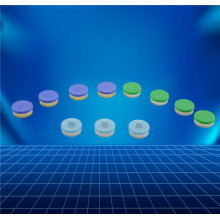

The Polypropylene Joint for Plastic Infusion Container is made of the imported medical‐class polypropylene; where the material complies with FDA rule and passes the USP CLASS VI test. Beneath the joint, itis a ship‐shape, which will form a plastic liquid infusion bag after welding with non‐PVC co‐extruded film; the top opening is the inlet for loading liquid medicine. After filling the liquid medicine, the top opening will be melted to seal with the composite cap, and then form a complete soft‐bag liquid infusion product. The joint is produced in the clean plant, with the overall plant reaching to Class 10,000 and some for Class 1,000,000. The main working procedures, such as the injection molding, inspection, cleaning, inner packing and so on, are designed and processed as per the cleanliness requirements at the partial level of Class 100 , which passes the GMP on‐site certification and complies with the cleanliness requirements of high capacity injection medicine.

The surface of production equipment is smooth, flat, and easy to clean and sterilize, with sound corrosion‐resistant property, and inert to make chemical reaction with packing material. The precision and sensitivity of test and inspection instruments comply with the test and inspection requirements of products.

The polypropylene joint for plastic infusion container is mainly used for the pipe of non‐PVC soft‐bag.